10

Vacuum clamping technology

We offer suitable solutions in the field of vacuum clamping technology and vacuum clamping plates. Reliable clamping of flat, flat metal workpieces, minimal set-up times and distortion-free work, e.g. in CNC machining centers.

Modular vacuum clamping system, vacuum clamps

The vacuum plate is particularly suitable for the reliable clamping of flat metal workpieces with flat undersides on CNC machining centers and guarantees minimal set-up times. Even components that are difficult to clamp mechanically can be fixed easily, quickly, precisely and without distortion using the vacuum clamping system.

The vacuum clamping technology, vacuum clamps enable:

- Short setup times

- Large holding force

- High precision

Flexible design of a complete vacuum clamping system

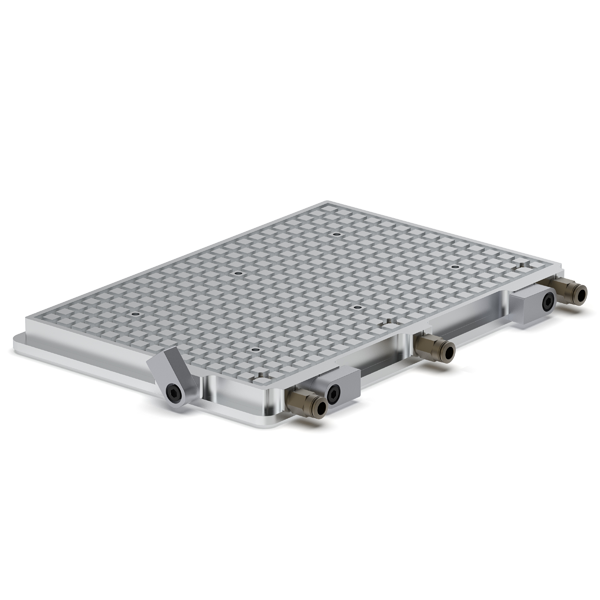

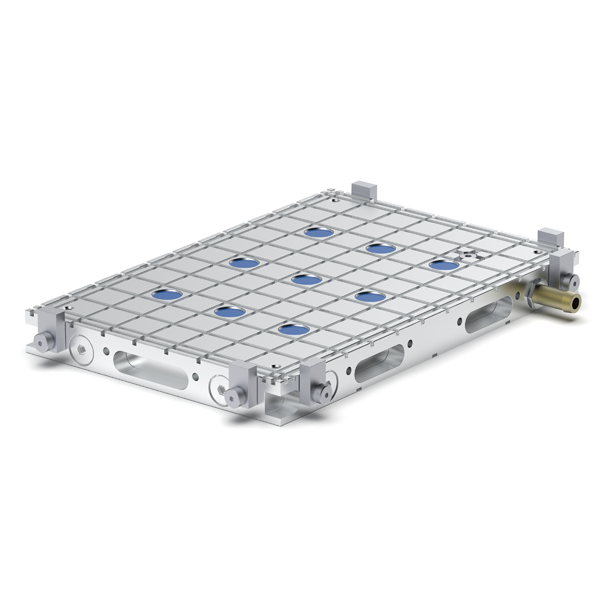

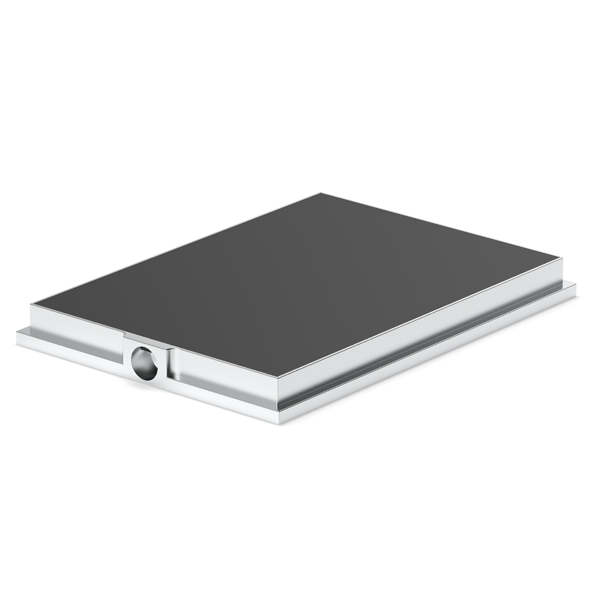

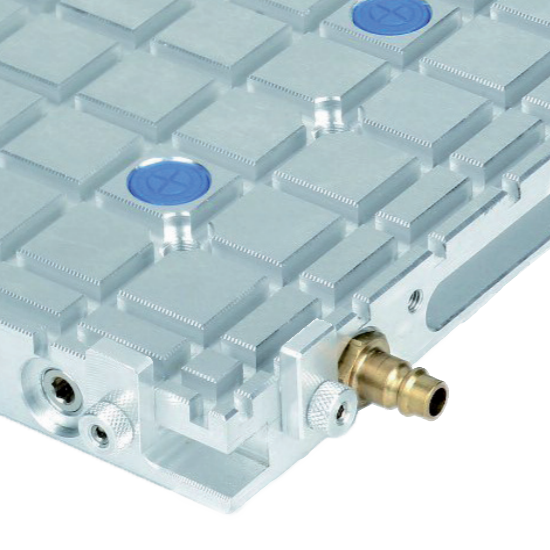

Vacuum plates

Exclusive spreader features:

Optional friction islands result in significantly higher absorption of transverse forces- High horizontal holding forces (up to 30% increase compared to vacuum plates without friction islands)

- No additional force effect of the friction islands on the workpiece

- Oil and ozone resistant, individually replaceable in case of wear

- Activation and deactivation automatically via vacuum supply

Vacuum clamping plate with friction pads

Active friction brush - Vacuum clamping plate

inactive friction brush - vacuum clamping plate

Examples of vacuum plates, vacuum clamping plates

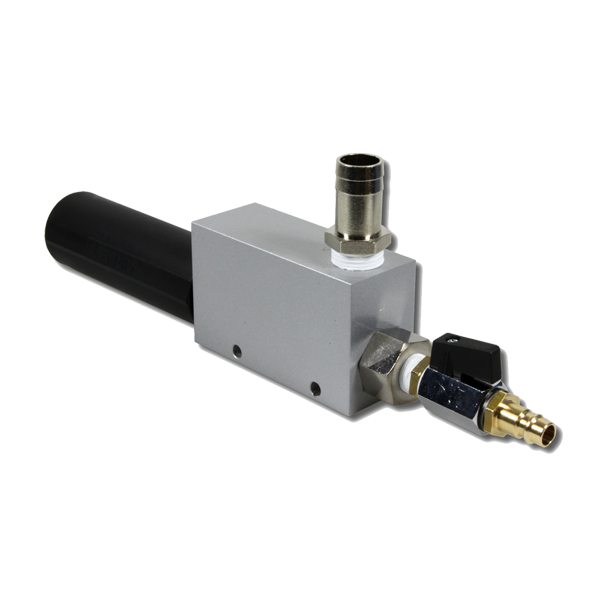

Vacuum unit and vacuum generator

Powerful system components

Vacuum units can be used to generate a constant vacuum. The vacuum units have a liquid separator and an oil-lubricated vacuum pump. They serve as an additional vacuum reservoir and can be used flexibly. The vacuum generator works with compressed air. No additional connections are required on the machine.Securely clamp complex workpieces

A coarse grid dimension is sufficient for processing simple workpieces. Complex workpieces with openings must also be sealed with a sealing cord at the corresponding points to ensure the system vacuum. When using a fine grid dimension, this sealing cord can be positioned close to the openings and recesses. This provides a flexible seal and minimizes clamping force losses.

Simple workpiece

- Geometrically simple structure

- Few webs and recesses/breakthroughs

- Bar width > 30 mm

Recommendation: grid dimension 25 x 25 mm

Complex workpiece

- Geometrically complex structure

- Many webs and recesses/breakthroughs

- Bar width < 30 mm

Recommendation: Grid dimension 12.5 x 12.5 mm

Clamping device

Clamping device for the aerospace industry

The sometimes very complex workpiece geometries in the aerospace industry usually require a special clamping solution adapted to the application. Maximum precision and gentle machining of the workpiece are particularly important here. We have already developed several successful solutions for customer-specific projects as part of special project planning. With the vacuum plate, even very thin workpieces can be fixed without damage and with process reliability. Minimizing set-up times and the high degree of flexibility are additional arguments in favour of the vacuum clamping system.Milling through

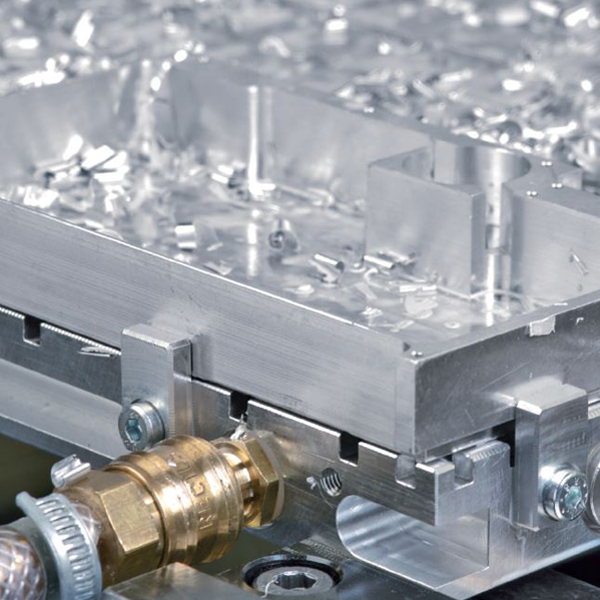

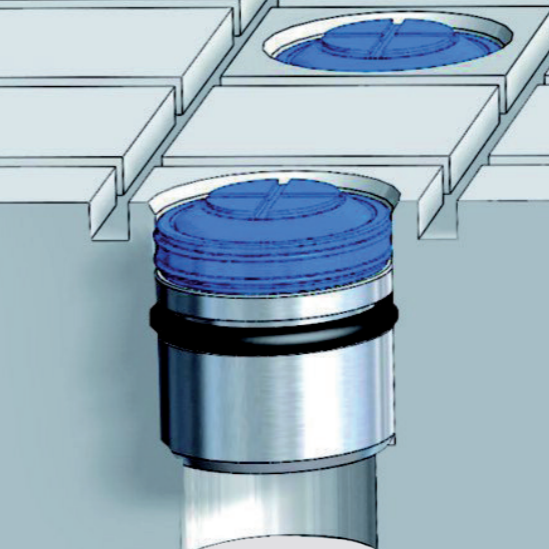

Milling through a workpiece with vacuum plate and grid table suction cups

The use of grid table suction cups enables the production of openings when processing workpieces. In the first step, processing is carried out with small height tolerances on the workpiece clamped on the vacuum plate. In the second step, the grid table suction cups are inserted directly into the grid of the vacuum plate and the suction cups are arranged according to the position of the drill holes. In this way, the workpiece can be drilled through without damaging the vacuum plate or the component itself.Clamping

Efficient clamping of aluminum cubes

The application shows a vacuum plate in use on a CNC machining center for metal processing. It is fixed to the machine table with the help of mechanical clamping devices. By using vacuum, the thin-walled underside of the workpiece can be clamped precisely and without distortion. This enables efficient 5-axis machining in a single clamping operation and the powerful AGG vacuum unit is used to generate the vacuum. Thanks to its compact design, it is mobile and can be moved ergonomically to the place of use using a handle and castors.What can we do for you?

By using our products and services, our customers increase the productivity of their production by up to 100 % and at the same time significantly reduce their production costs.