7

Concentricity tester | Concentricity measuring device

Concentricity measurement, concentricity testing directly on the machine. We offer centerless concentricity testers, concentricity testers with support prisms, concentricity testers with rolling blocks and concentricity testers with tailstocks. The concentricity test can be carried out within 10 seconds without prior knowledge.

Concentricity testers | Concentricity measuring devices

Spreitzer concentricity testers offer high flexibility, fast set-up times, high concentricity accuracy and are suitable for different geometries. The concentricity testers are used for testing external, internal and flat surfaces of rotating parts. The concentricity of a round profile is of considerable importance for the manufacture of shafts, bushes, gears or bearings. Examples from the automotive industry: camshafts, crankshafts, cardan shafts, drive shafts. Our concentricity measuring devices can be used to determine the coaxiality of two or more diameters and to carry out axial run-out measurements. In the RPG, RPG AL RPG mini and RPG micro type, the workpiece is unwound between three rollers without a center. A concentricity of 0.002 mm is achieved. The robust construction with preloaded roller bearings of the support rollers is designed for a long service life. A diameter range from 0.8 to 240 mm can be covered with the corresponding design variants.

What does concentricity testing mean?

Concentricity testing is a method of checking the accuracy of machine parts, especially rotating parts such as axes, tool spindles or workpiece clamping devices. It is an important quality control measure in metalworking and other industries where precision and accuracy play a major role.

The concentricity test is carried out by clamping the component to be tested in the clamping device and setting it in a rotary motion. During rotation, the component is measured with a dial gauge holder and a dial gauge to determine whether the component runs exactly true and whether it exhibits deviations in shape or alignment.

Depending on the tolerance and the intended use of the component, different levels of testing may be required. The inspection can be performed manually or automatically, with modern CNC machines being able to perform the concentricity test automatically and monitor the results in real time.

Concentricity testing is an important method for ensuring the quality and accuracy of machine parts and plays an important role in modern manufacturing. It helps to detect errors at an early stage and increase production efficiency by avoiding rejects and unnecessary repetitions.

Form and position tolerances | Inspection options

In the measurement technology, concentricity gages occupy a particularly important position.

A suitable measuring setup as well as corresponding precision of the concentricity gage are the basis for a precise measurement.

Explanation of terms Position tolerances

Circularity: The circumferential line must be perpendicular to the center axis between two concentric circles in all section planes.

Perpendicularity: for surfaces: the surface must lie between two planes perpendicular to the reference.

for axes: the cylinder axis must be in a cylinder perpendicular to the reference surface.

Radial runout: The uniformity of a rotating circular workpiece.

During one revolution around the reference axis, the runout must not exceed a specified value.

Total, radial and axial runout: In the case of multiple rotation about the reference axis and simultaneous axial or radial displacement, the radial runout or axial runout must not exceed a specified value.

Concentricity and coaxiality: The center of the toleranced circle must be in a circle whose center is concentric to the reference.

The axis of the toleranced surface must be in a cylinder whose central axis is coaxial with the reference.

Coaxiality and concentricity deviation. Deviations that refer to a reference axis.

The workpiece rotates around this axis when the toleranced element is measured.

Runout deviations occur due to axis misalignment, lack of coaxiality or due to roundness deviations

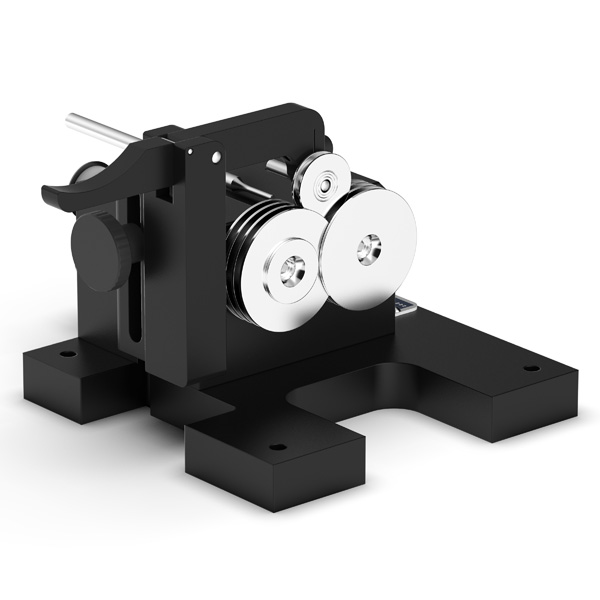

Runout testers, centerless

Centerless concentricity testers for measuring and testing tasks on external surfaces, internal surfaces and flat surfaces. Suitable for single and series testing, for single-sided measurement. Measurements on both sides possible with accessories.

Measuring principle centerless concentricity gauges

Concentricity testers with rolling blocks

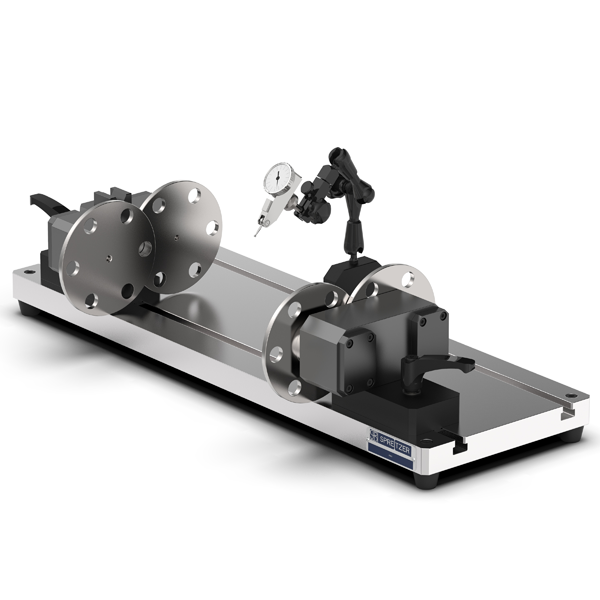

Concentricity testers with support prisms

Measuring principle concentricity gauges with V-blocks

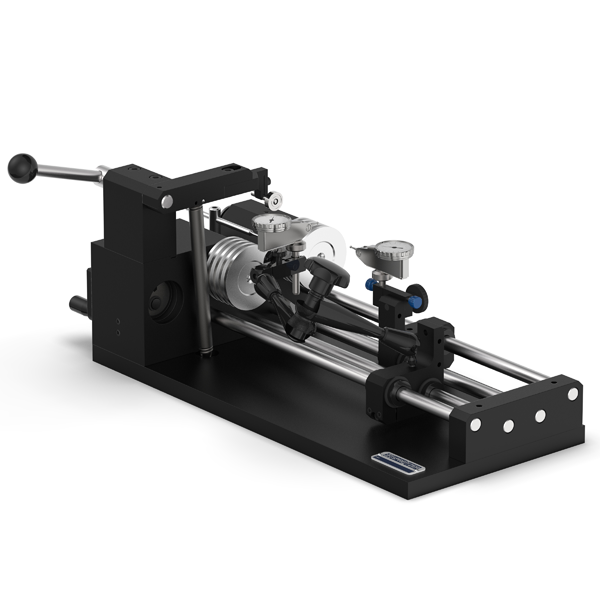

Concentricity testers with tailstocks

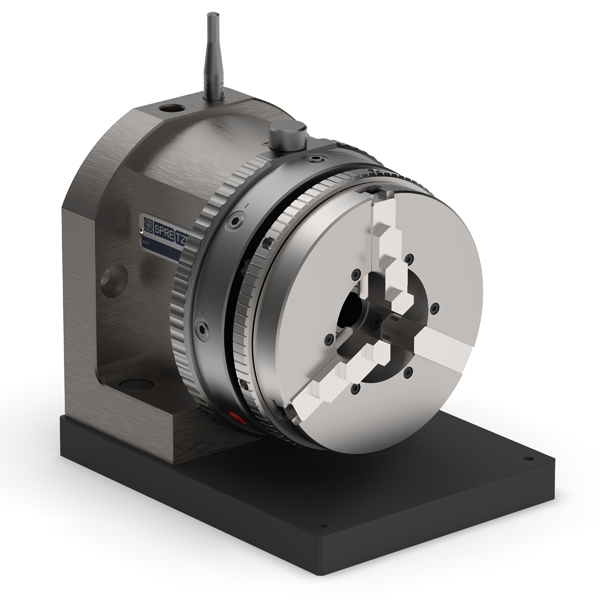

Precision rotary units

3 practical tips for your success

Precise concentricity testing.

Within 10 seconds.

Without prior knowledge.

Directly on the machine.

- Drastically reduces your internal and external error costs!

- Reduces the set-up and downtime of your expensive CNC machine by up to 80 %!

- Effective due to easy handling.

Indispensable!

What can we do for you?

Reduce your production costs. Measuring tasks solved precisely within seconds.