1

Universal clamping system

We offer suitable solutions in the field of universal clamping systems that are as varied as they are diverse – we are ready for your requirements.

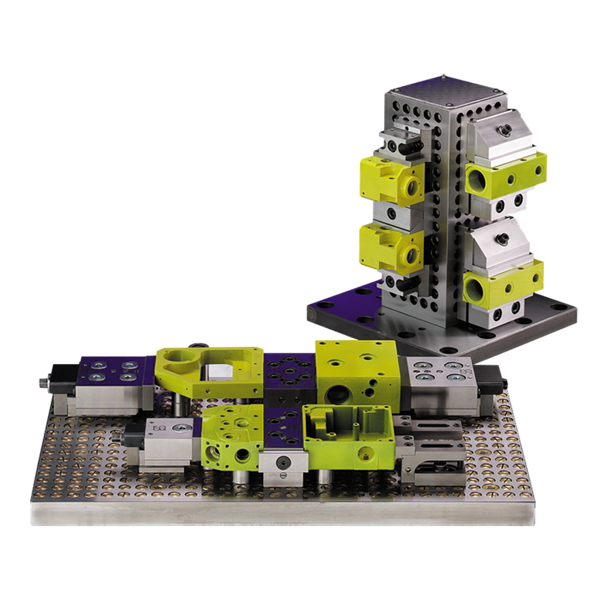

The Universal Clamping System is a modular construction kit that can be assembled, for example, from basic or clamping elements to form a clamping device.

Modular clamping system

The Universal Clamping System is a modular clamping system based on a drilling system and offered in three different grid types.

Different basic, clamping and support elements can be combined system-logically by detachable connections to form a device corresponding to the application.

The universal clamping system is designed for single part as well as small batch production and with multiple clamping also for large batch production.

Due to the reusability of the components, the universal clamping system can be used flexibly and cost-effectively.

Basic elements

Clamping cubes, clamping blocks and double angles are made of nodular cast iron and are therefore extremely stable, torsion-resistant and vibration-damping.

In addition, clamping plates made of tempered and surface-hardened tool steel are available in various dimensions.

The support and clamping surfaces of the basic elements are precision ground.

Different designs can be individually adapted to the respective machine table.

Clamping and support elements

A variety of clamping elements such as mechanical, pneumatic, electromechanical and hydraulic centric clamps as well as clamping block, fixed block units, pull-down and support clamps allow distortion-free clamping.

Various support rails, support rollers and stops allow exact positioning on the base elements.

Hook clamps, lever clamps and front clamps clamp the parts to be machined.

Support blocks serve as support elements and stabilize the workpiece during the cutting process.

Image: Machine-specific clamping plates with clamping cube

Tension bridges

CNC rotary tables are used for 3- and 4-sided machining as an optional 4th axis on vertical machining centers.

Both in single part and small batch production as well as in large batch production.

By attaching a suitable clamping bridge to the CNC rotary table, 3- and 4-sided machining of several workpieces is achieved in one machining cycle.

Image: Tension bridge with cradle plate

What can we do for you?

By using our products and services, our customers increase the productivity of their production by up to 100 % and at the same time significantly reduce their production costs.