5

Alumess.easyloc - Clamping system for laser processing

ALUMESS.easyloc – modular clamping devices for laser marking, laser engraving and laser welding.

Workpieces can leave production perfectly marked.

ALUMESS.easyloc - Fixing system for laser processing

Advantages

- Is the only prefabricated, quick-change, modular fixing system for laser marking, laser engraving and laser welding

- Can be easily installed on any equipment

- Speeds up your process so you can mark more workpieces per shift

- Is risk-free – if the system does not meet your expectations, you can simply return it for a full refund.

Pallets and clamping devices can be combined

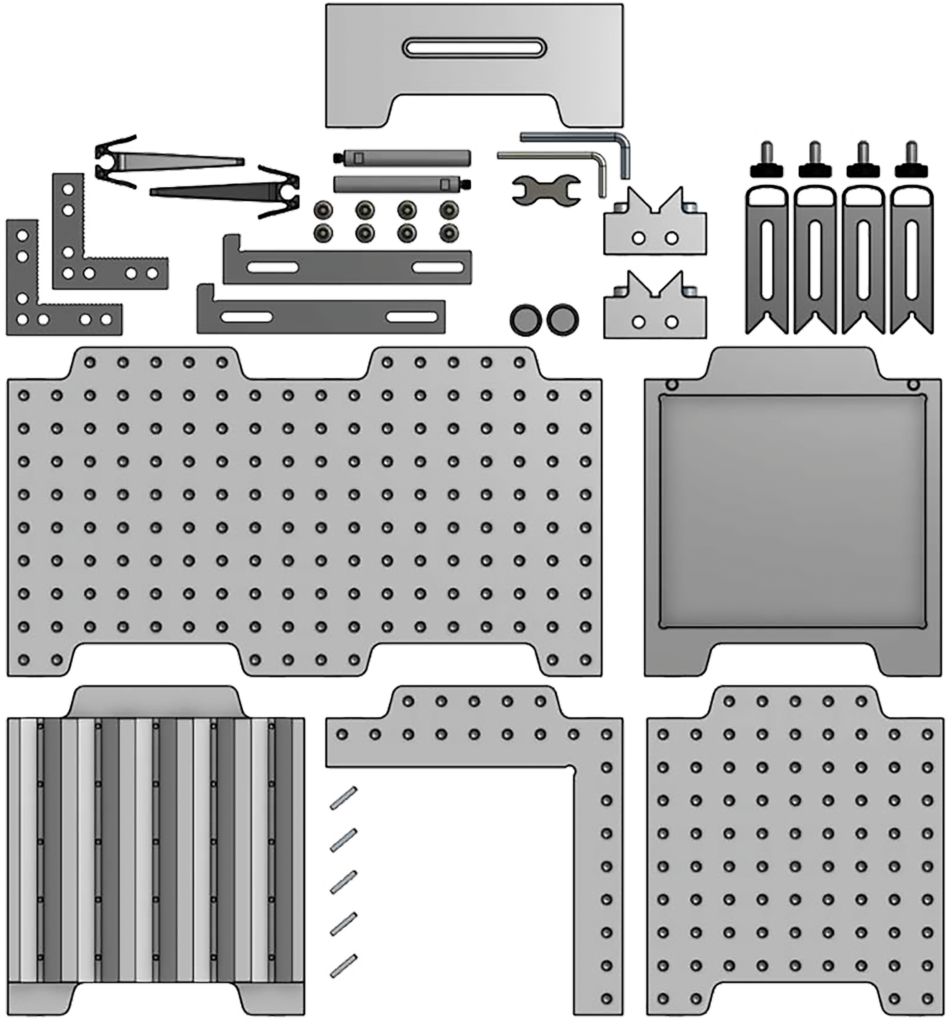

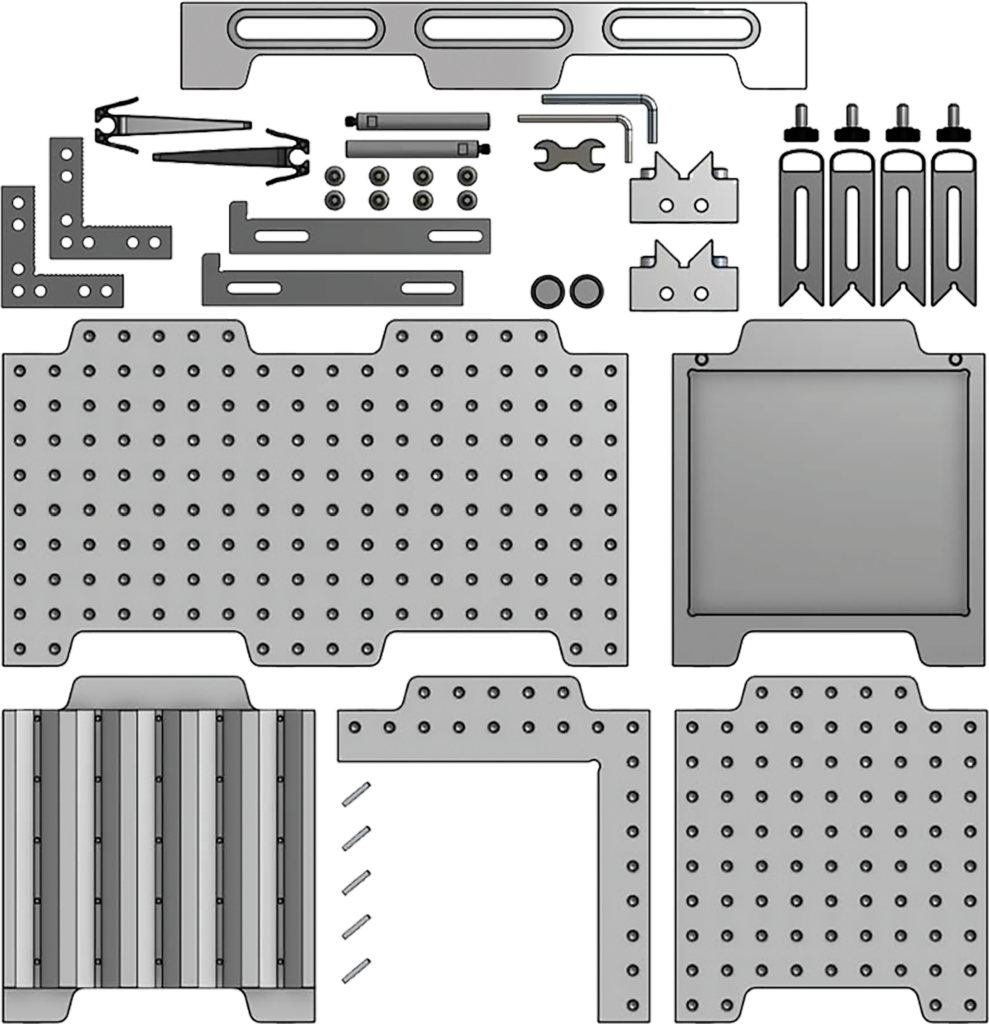

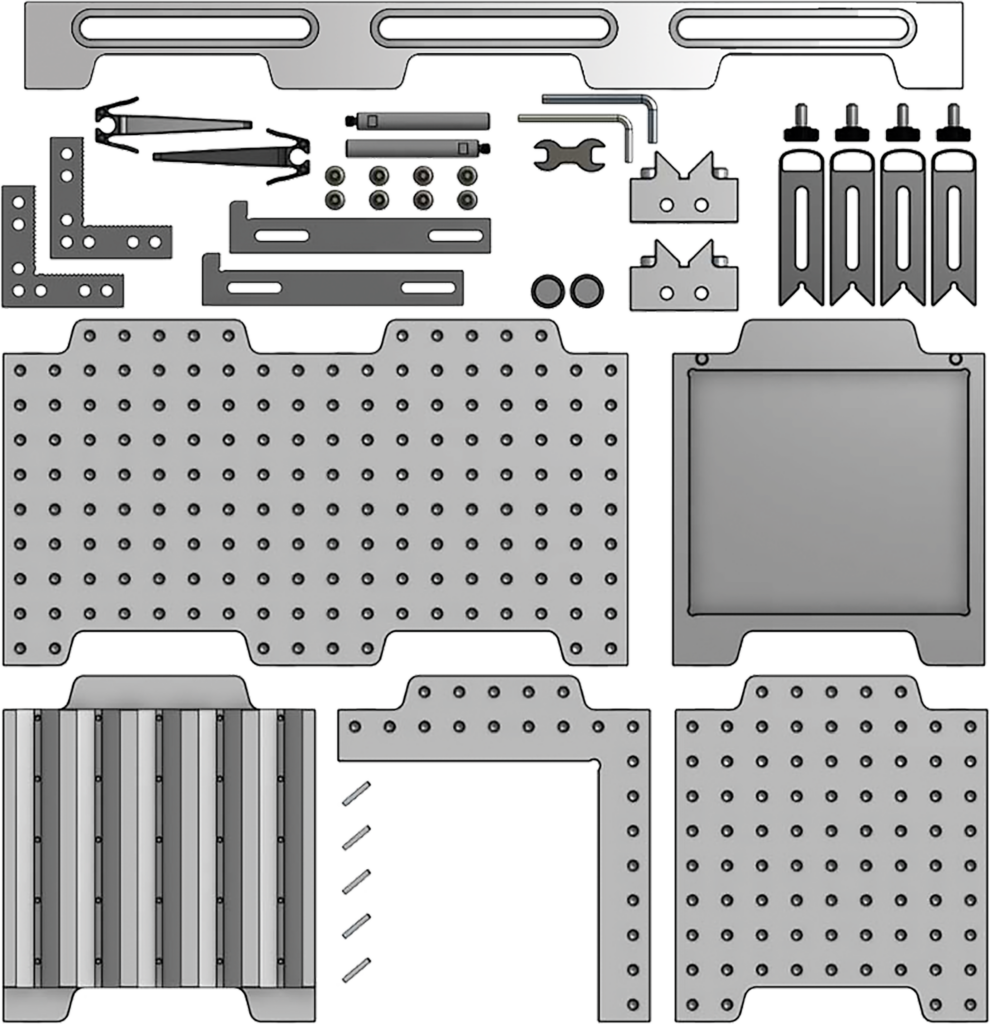

ALUMESS.easyloc starter sets for laser processing

Our ALUMESS.easyloc sets for laser marking systems are the only universal, easy-to-use and ready-made quick-swap fixture system for laser marking applications and laser engraving.

They can be configured easily, individually and machine-specifically.

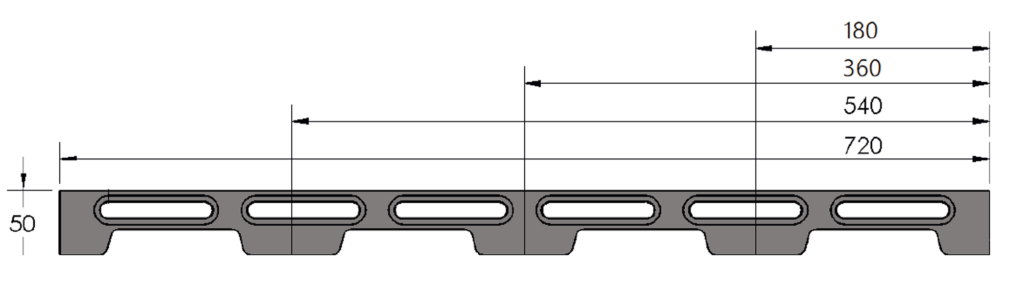

The suitable docking rail is mounted on the laser marking system.

The magnetic, interlocking interchangeable pallets hold the workpieces by means of universal fixing elements.

Loading the system is child’s play.

Alumess.easyloc Laser Set (inch version) in 5S foam organizer

ALUMESS.easyloc extension – clamping device set LA

- laser marking

- laser engraving

- laser welding

Technical data

- Pallet size: Height 12.7 mm

- Hole pattern: 20×20 mm

- Thread: M6

System advantages

- Simplest assembly

- Changeover in seconds

- Fixation according to contour

- Flexible combinable

Basic elements

Pallet 3618

Pallet 1818

Connection strip 180 / 360 / 540 / 720

Assembly examples ALUMESS.easyloc clamping device

Our ALUMESS.easyloc starter sets for laser processing

Inspection Arsenal® and Laser Arsenal® are registered trademarks of Phillips Precision, Inc., USA. Since 2021 we are the exclusive partner for Europe, Asia and other international sales territories

ALUMESS.easyloc - a case study

What can we do for you?

By using our products and services, our customers increase the productivity of their production by up to 100 % and at the same time significantly reduce their production costs.