2

Automation solutions for machine tools

Automated pallet changers, workpiece grippers and mobile robot systems for efficient pallet and workpiece automation.

Highest reliability, robust technology for 24/7 production.

Automation in the manufacturing industry

The manufacturing industry operates under different conditions today than it did a few years ago.

Customers are demanding shorter and shorter delivery times, and smaller and smaller series are in demand.

Products have to be manufactured with ever smaller tolerances, prices are constantly falling and competition is now global.

These new conditions must be met with increased flexibility, improved quality and increased productivity.

In the longer term, this can only be managed by automated production!

Automation takes monotonous and time-consuming work away from your highly skilled employees so they can focus on more demanding tasks.

In automated operation, your production runs around the clock – seven days a week.

- Strengths:

- Higher productivity

- Maximum flexibility

- Shorter lead time

- Unit cost reduction

- Faster return on investment

Automatic pallet changer

Pallet changer SP-APC 1

The SP-APC 1 pallet changer requires a minimum of floor space in front of the machine.

With glass doors over one full side, the SP-APC 1 pallet changer offers maximum access to the magazine.

This greatly facilitates the loading and unloading of pallets.

The system is easy to install and features a quick return on investment.

- Strengths:

- Compact design, 1200 × 1200 × 1870 mm

- Economical, universally expandable

- Easy installation

- Compatible with all common CNC control units

This extremely compact automation system is a user-friendly pallet changer for automatically changing clamping devices or pallets onto the machine table.

Tip: Installation, instruction and service by our system partners worldwide.

Pallet changer SP-APC 2

The SP-APC 2 automatic pallet changer offers maximum magazine capacity with a minimum footprint. The modular design means that the magazine capacity is extremely flexible and can be adapted to the customer’s needs. If you start with one pallet magazine, you can always add one or two more magazines.

- Strengths:

- Compact design, 1270 × 1735 × 2250 mm (depending on magazine type)

- Universally expandable, 10 - 240 pallets (1 - 3 magazines)

- C-axis 330° rotatable

- Easy installation

- Compatible with all common CNC control units

SATISFACTION GUARANTEE – OVER 600 SYSTEMS SUCCESSFULLY IN USE WORLDWIDE

Workpiece automation

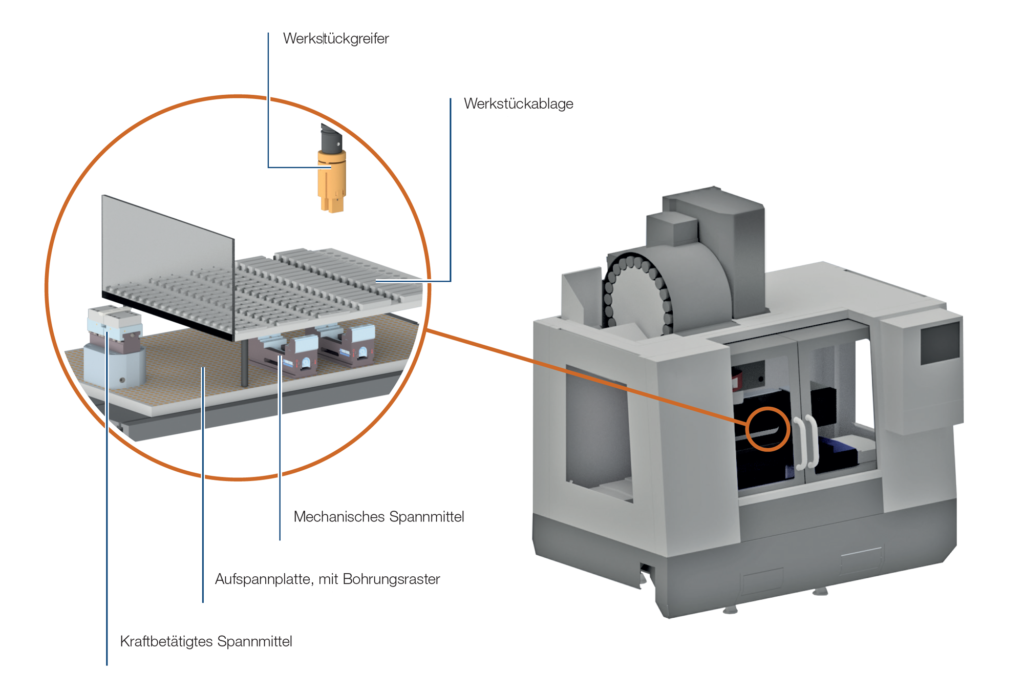

Workpiece gripper

With the help of the workpiece gripper, you can use your existing machine tool as an automation cell. The gripper, which is operated pneumatically or by means of cooling lubricant, is available in various designs. It is inserted into the machine from the tool store to transport workpieces from the workpiece storage area to our power-operated clamping devices. The workpiece gripper loads lathes, milling machines, grinding machines, eroding machines and measuring machines.- Strengths:

- Cost-effective

- Easy installation

- High gripping force, adjustable

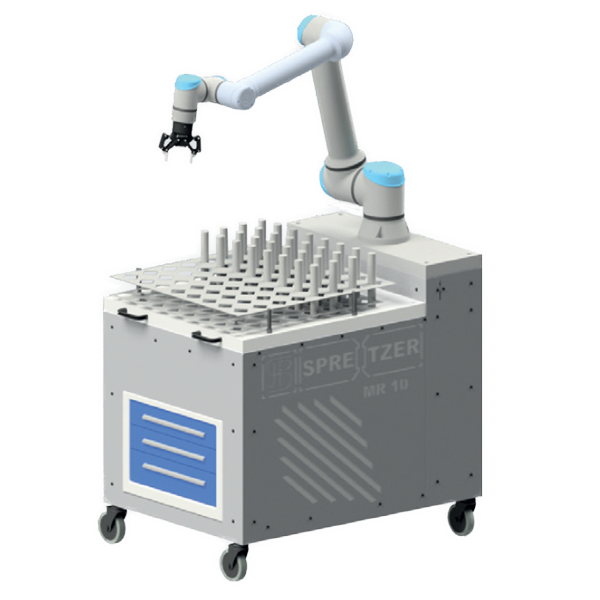

Mobile robot system SP-MR 1

This mobile and compact automation system provides a quick introduction to robot automation. It supports and relieves employees, loads CNC machines or assembles components.The open, fence-free access allows flexible working.

The system is easy to install, can be used on multiple machines, and features a quick return on investment.

- Strengths:

- Compact design, 1200 × 800 mm

- Easy handling

- Flexible use

- Operation possible without barrier

What can we offer you?

In automated operation, your production runs around the clock - seven days a week. We offer customized solutions for every automation requirement. Highly efficient, reliable and economical.