2

Clamping jaws

Versatile clamping jaw variants for different customer requirements. Stepped clamping jaws, reversible jaws, clamping jaws with coating and grip clamping jaws, which eliminate the need to pre-stamp the workpieces to be machined. We offer clamping jaws for centric clamps and jaw chucks as well as clamping jaws that we manufacture directly to customer specifications. Our wide selection guarantees you the best possible solutions.

Clamping jaws

Wide range for a secure hold.

Clamping jaws for centric clamps, center vices, machine vices. Clamping jaws with grip for blank clamping without pre-stamping. Coated clamping jaws for clamping ground workpieces and soft clamping jaws for producing shaped jaws.

For self-production of mold jaws or for clamping of molded parts.

For clamping finished parts or for use in second clamping.

High holding force due to increased friction factor. The workpiece surface is not damaged.

For clamping hard raw material. The hardened and coated surface of the clamping jaws penetrates the workpiece surface during the clamping process.

Angular errors of several millimeters can be compensated with the pull-down pendulum jaws.

Prism jaws hardened and ground for clamping round workpieces.

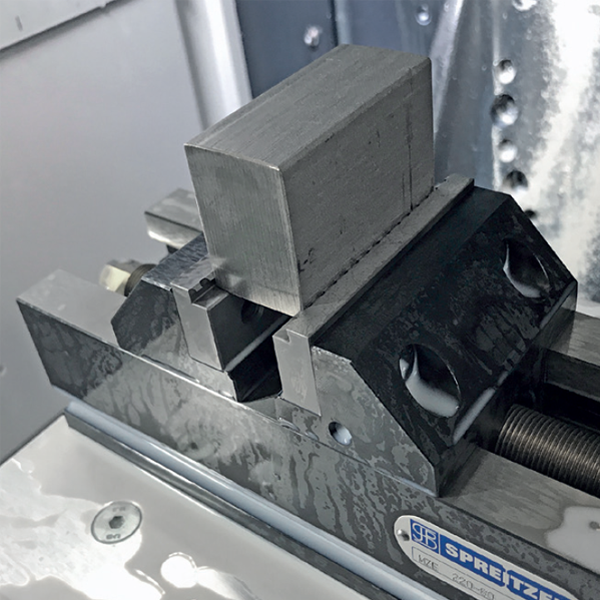

Grip clamping jaws

MZE 220-80 centric clamp with grip jaws

Secure clamping of blanks without pre-stamping

Workpiece blank clamping or machining requires new and innovative clamping solutions, especially on multi-axis machining centers.

The high inherent rigidity, the optimum guide ratio and the powerful spindle result in high and effectively acting clamping forces.

Process-safe clamping with Grip(s)

- No embossing station necessary.

Embossing and clamping take place in a single operation - High holding forces due to material-specific grip jaws

- Less material required due to clamping depth of only 4 mm

- Highest machining quality due to distortion-free clamping and less vibration

Rapid Fixture

Customized clamping jaws

Do you need workpiece-specific clamping jaws for your production? In OEM quality – competent, fast and flexible. We manufacture form-fitting workpiece clamping jaws using the latest manufacturing methods. Cutting or non-cutting, individually for your workpieces and according to your requirements. Production using 3D rapid prototyping is particularly economical for fine, small contours.

Realization in 5 steps

1. you send us your 2D or 3D STEP data of the workpiece with background information on the necessary machining positions and the possible interfering contour.

2. you provide us with the type of vice you are using and, if necessary, the manufacturer.

3. choose from different materials and surfaces:

- Plastic

- Aluminum

- Steel

- Surface hardened

- Ground

- HM coated

- etc.

4. we select the appropriate manufacturing process.

(3D Rapid Prototyping, 3D Milling)

5 We will provide you with a detailed quotation with price and delivery time for your individual clamping jaws.

What can we do for you?

By using our products and services, our customers increase the productivity of their production by up to 100 % and at the same time significantly reduce their production costs.