CLAMPING SOLUTIONS FOR AUTOMATION SYSTEMS

CLAMPING SOLUTIONS FOR AUTOMATION SYSTEMS

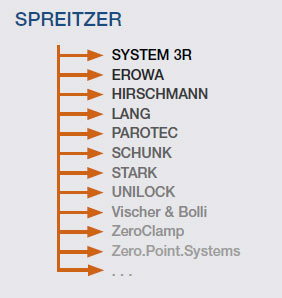

SPREITZER realizes state-of-the-art clamping concepts for your automation solutions. Better clamping. Better milling. Our automation clamps can be operated mechanically, hydraulically or pneumatically and are available for the Erowa, System 3R and Lang Quick Point palletizing systems, for example.

CLAMPING TECHNOLOGY FOR PALLET AUTOMATION

SPREITZER develops clamping concepts for your automation solutions.

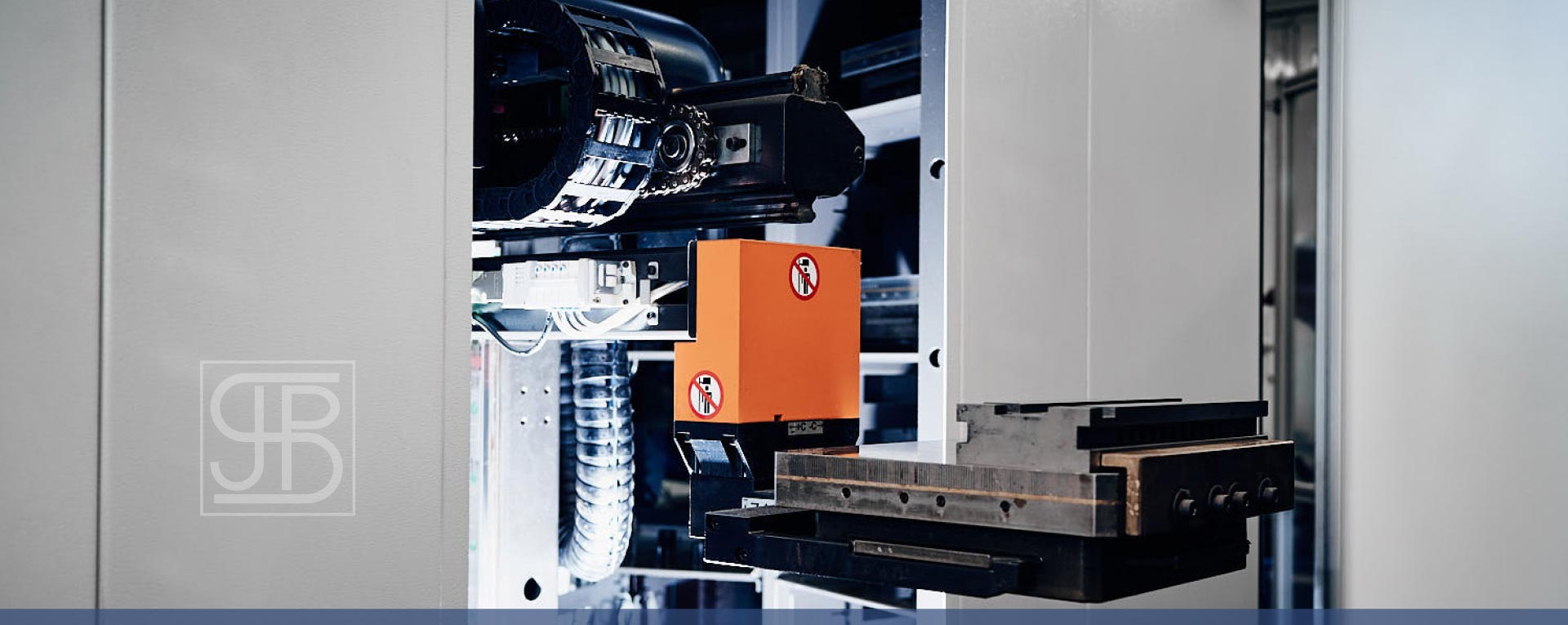

Automated, computer-controlled pallet changers enable fast loading and unloading of processing machines.

We offer efficient and modular clamping technology for pallet automation. pallet automation.

Here, the focus is on maximum performance andperformance and variability of the clamping device an economical investment sum.

Strength:

- Economic efficiency

What is pallet automation?

Pallet automation refers to the use of automated systems and technologies to handle pallets in industrial environments. The main objective is to make the transport, storage and staging of goods on pallets more efficient and productive.

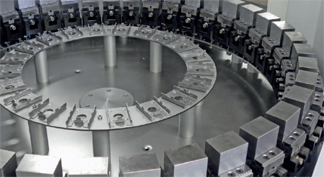

Pallet automation involves the use of various devices and machines to automate the entire pallet handling process. This includes the use of automated conveyor belts, forklift robots, pallet racks and palletizing robots.

A central component of pallet automation is the automatic loading and unloading of pallets. Robots or specialized machines can move pallets from one station to the next to unload or pick up goods. This process can also be combined with automated racking systems to store pallets safely and in a space-saving manner.

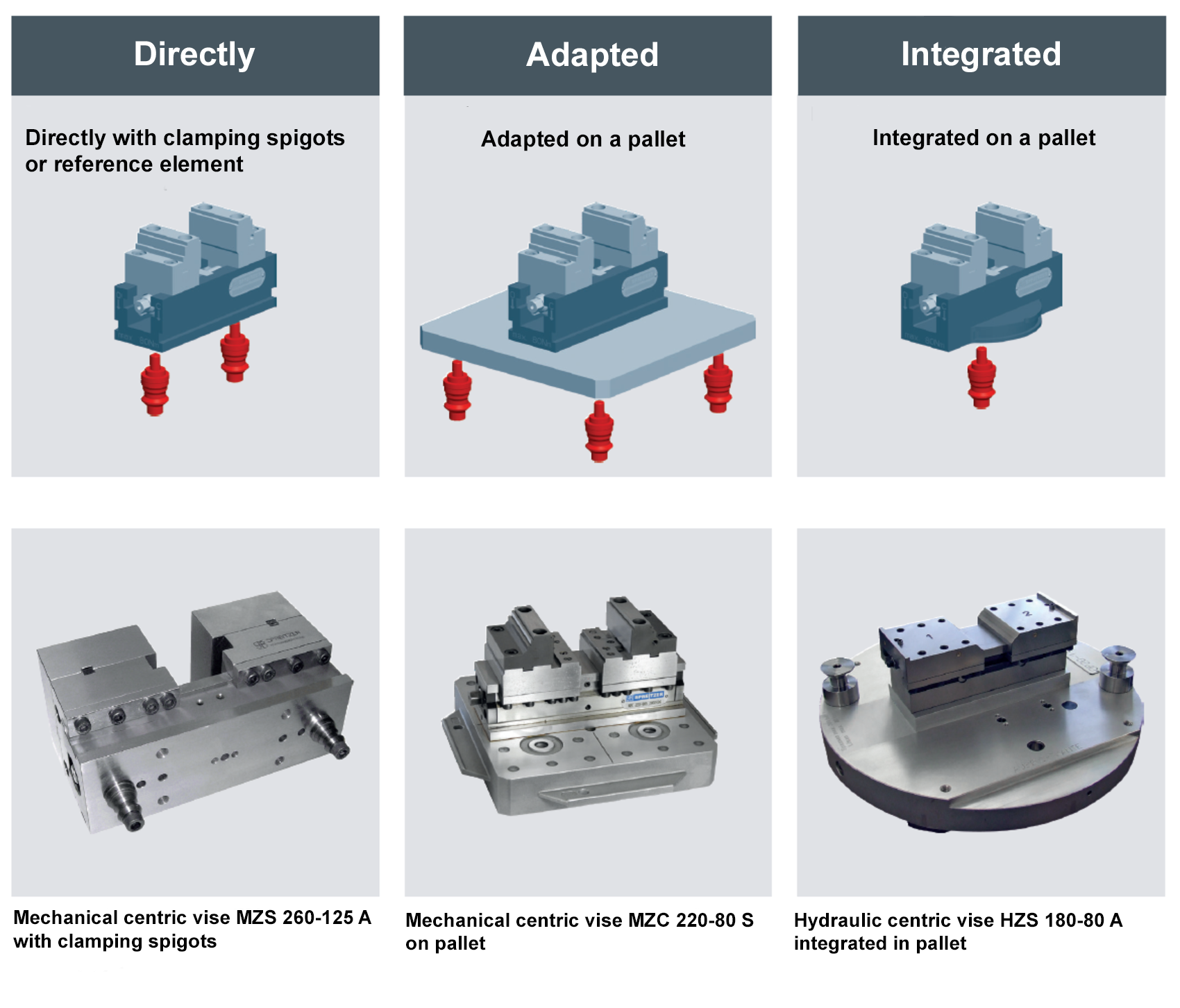

The mounting hole pattern on the underside of our centering clamps, compact clamps and alternative clamping devices enables them to be combined with various zero point clamping systems or is used for easy mounting on commercially available palletizing and automation systems. At the customer’s request, the centric clamps and compact clamps are available as completely integrated versions or as automation clamps for automation systems from a wide range of manufacturers.

Combination options with zero point clamping system or palletizing and automation systems

AUTOMATION CLAMPS

The advantages of automation clamps are their reliability, precision and repeatability. Automatic tension regulation allows components to be fixed in the correct position, enabling accurate machining or assembly. This improves the quality of the manufactured products and reduces the reject rate. In addition, automation clamps increase productivity because clamping operations can be performed faster and more efficiently.

Another important aspect of automation clamps is their flexibility. They can be easily adapted to different workpieces or fixtures for versatility. Their rugged design and materials make them suitable for use in demanding environments.

The advancing automation in industry has increased the demand for reliable and efficient workholding solutions. Automation clamps play a crucial role in optimizing production processes and increasing efficiency. They help to reduce labor costs, increase production speed and improve the quality of manufactured products.

Overall, automation clamps offer a cost-effective and effective solution for automated manufacturing. With their help, companies can optimize their production processes and remain competitive. The continuous development of automation clamps promises even more powerful and versatile clamping solutions for industry in the future.

Our mechanical, pneumatic or hydraulic automation clamps with integrated interface to various zero point clamping systems offer the best possible accessibility in 5- and multi-sided machining as well as low transport weight.

+ Strengths:

- No adapter plates

- Fewer interfaces

- Less weight

Practical tip: The outer contour / gripper track of the automation clamps can be adapted according to customer requirements.

Examples automation clamps

Mechanical centering vise MZR 160-60 PA, System 3R Magnum

Mechanical centering vise MZE 160-60 PA, System 3R Magnum

Mechanical centering vise MZU 160-60 PA, System 3R Magnum

Mechanical centering vise MZQ 160-60 PA, System 3R Magnum

Mechanical centre-clamping vise MZR 160-60 PA,

Customized variant

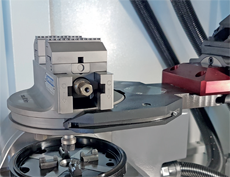

Mechanical centre-clamping vise MZQ 110-60

on automatic pallet changer SP-APC 1

Mechanical centering vise MZQ

170-60 PA, Erowa ITS 148

AUTOMATION CLAMPS – DIFFERENT TYPES CENTRE-CLAMPING VISES / CENTRIC CLAMPS

| Type | Ø base body (mm) | Length base body (mm) | Jaw width (mm) | Stroke (2xmm) | Span (mm) | Clamping force (N) | Available for: Zero point clamping system / palletizing system |

|---|---|---|---|---|---|---|---|

| MZR 80-36 PA | 80 | 80 | 36 | 19 | 59 | 16 000 | Erowa ITS 50 System 3R GPS 70 System 3R Macro 54 System 3R Macro 70 … |

| MZE 80-36 PA | 80 | 80 | 36 | 18 | 40 | 16 000 | ^ |

| MZU 80-36 PA | 80 | 80 | 36 | 19 | 78 | 16 000 | ^ |

| MZS 80-36 (A) PA | 80 | 80 | 36 | 16 | 80 | 16 000 | ^ |

| MZR 120-36 PA | 120 | 120 | 36 | 39 | 99 | 16 000 | Erowa ITS 115 System 3R GPS 120 System 3R Macro 70 System 3R Macro 116 System 3R Matrix 110 … |

| MZE 120-36 PA | 120 | 120 | 36 | 39 | 80 | 16 000 | ^ |

| MZU 120-36 PA | 120 | 120 | 36 | 39 | 118 | 16 000 | ^ |

| MZR 150-60 PA | 148 | 148 | 60 | 34 | 114 | 30 000 | Erowa ITS 148 / MTS System 3R GPS 120 System 3R Macro 116 System 3R Matrix 142 … |

| MZE 150-60 PA | 148 | 148 | 60 | 33 | 68 | 30 000 | ^ |

| MZU 150-60 PA | 148 | 148 | 60 | 31 | 108 | 30 000 | ^ |

| MZQ 150-60 PA | 148 | 148 | 60 | 34 | 114 | 30 000 | ^ |

| MZS 150-60 (A) PA | 148 | 148 | 60 | 37 | 148 | 16 000 | ^ |

| MZR 160-60 PA | 160 | 160 | 60 | 40 | 126 | 30 000 | Erowa ITS 148 / MTS LANG Quick Point 52 / 96 System 3R GPS 120 System 3R Magnum System 3R Matrix 142 … |

| MZR 160-60 PA | 160 | 160 | 80 | 34 | 118 | 40 000 | ^ |

| MZE 160-60 PA | 160 | 160 | 60 | 39 | 80 | 30 000 | ^ |

| MZE 160-60 PA | 160 | 160 | 80 | 27 | 70 | 40 000 | ^ |

| MZU 160-60 PA | 160 | 160 | 60 | 37 | 120 | 30 000 | ^ |

| MZU 160-60 PA | 160 | 160 | 80 | 31 | 120 | 40 000 | ^ |

| MZQ 160-60 PA | 160 | 160 | 60 | 40 | 116 | 30 000 | ^ |

| MZQ 160-60 PA | 160 | 160 | 80 | 30 | 108 | 40 000 | ^ |

| MZS 160-60 (A) PA | 160 | 160 | 60 | 43 | 160 | 16 000 | ^ |

| MZS 160-60 (A) PA | 160 | 160 | 80 | 25 | 160 | 30 000 | ^ |

CLAMPING TECHNOLOGY FOR WORKPIECE AUTOMATION

Workpiece automation refers to the use of automated systems and technologies to optimize the handling of workpieces in industrial manufacturing processes. The goal is to increase efficiency, precision and productivity by reducing the workload of human workers and minimizing potential sources of error.

The benefits of workpiece automation include increased production speed, improved product quality and reduced costs. Automated systems can machine or assemble workpieces in a short time and with high precision. This reduces lead time and increases production capacity. At the same time, possible sources of error are minimized, as the automated systems usually have a high level of repeatability.

Another advantage of workpiece automation is the improvement of work safety. By using automated systems, hazardous or repetitive tasks can be taken over by employees. This reduces accidents and injuries and allows employees to focus on more demanding activities that require their skills and expertise.

We manufacture high-performance clamping solutions in the field of workpiece automation. Our pneumatic, hydraulic and electromechanical clamping devices allow universal use. We develop and supply customized designed clamping fixtures and fixture units for the multiple assembly of your manufacturing cell.

Mechanical centering vise MZQ

170-60 PA, Erowa ITS 148

Hydraulic centric clamping device HZS 120-60 in automation cell

Pneumatic centric clamping device PZS2 120-60 in automation cell on palletizing system

Hydraulic centric clamping device HZS 180-80 in automation cell

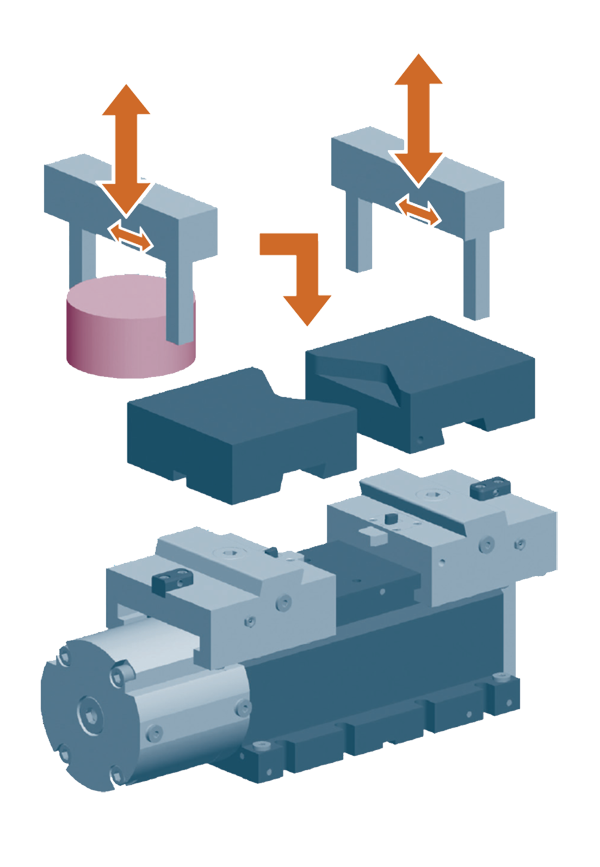

JAW QUICK-CHANGE SYSTEM

Automated exchange of workpiece and clamping jaws within automation cells.

Customized clamping jaws, HZS 250-100 A

Replace clamping jaws automatically

Within flexible manufacturing cells in the field of workpiece automation, it is inevitable that not only the workpieces have to be loaded and unloaded. The automated change of clamping devices and jaws is also imperative in order to machine a wide variety of parts unmanned.

With our solutions, different clamping jaws can be changed fully automatically by means of industrial robots and grippers within seconds in an operationally reliable manner.

The system works self-locking and is unlocked and locked without further mechanical operation.

+ Strengths:

- System operates without further mechanical actuation

- Clamping jaw change can be automated

- Clamping jaw change within seconds

- Completely integrated system

- Self-locking

Available for:

- Hydraulic centric vise HZS 180-100 A

- Hydraulic centric vise HZS 250-100 A

- Hydraulic centric vise HZS 300-125 A

- Electromechanical centric clamping device EZC 220-80

- Electromechanical centric clamping device EZC 280-100

Other versions available on request. Technical details, see separate product information.

WHAT WE CAN OFFER YOU?

In automated operation, your production runs around the clock – seven days a week. We offer needs-based solutions for every automation requirement. Highly efficient, reliable and economical.